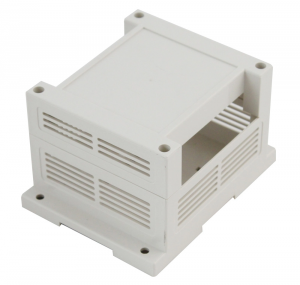

Waterproof Plastic Enclosure Box Electronic Housing Instrument Case Electrical Project Outdoor Junction Box

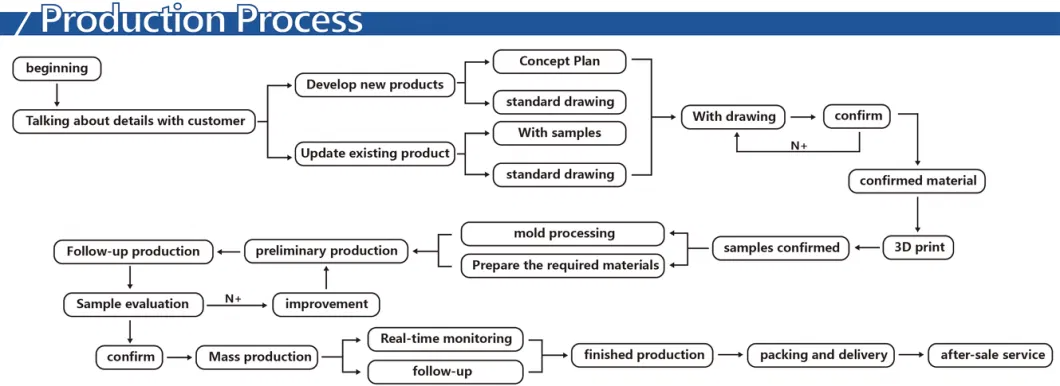

All of our products are Custom Moulded according to your Drawing, Sample and Idea. Till now we have produced products used for industrial, such as various industrial equipment components; Auto & MOTO, such as internal and external accessories, lights, rear-view mirrors, handles, bumpers and other components; Construction, plastic components for house insulation system, rain store system and drainage system; Daily use, such as plastic parts of fridge, air-condition, TV set; plastic case, container and box and so on; Garden tools, such as various plastic rakes, plastic tool handles; Furniture, various plastic caps for slat bed frame; other plastic accessories for furniture. We also do various multi purpose plastic interlocking floor tiles to be used for gymnasium, garage and office.

Also we have our own molds plant. Our mold engineers have skill of using UG, Pro/e, SolidWorks, CAD and other 3D design software to design the molds. We have Large CNC machining centers, CNC engraving machines, EDM spark molding machines and Line cutting machines etc to produce the molds.

Product Description:

|

Material |

PP, PS, ABS |

|

Color |

Any color available |

|

Package |

Standard export carton |

|

Sample Time |

5-7 working days |

|

Logo |

Provide Pantone color code, logo design, size |

|

Design |

AI, CAD, Core Draw,Original sample |

1.OEM/ODM orders are acceptable.

2. Manufacture your own plastic products with LOGO.

3. Excellent design team,

4. Skilled technical team

5. Advanced machines and equipment.

6. Professional sales staffs

7. Active service team

8. Material:PP/P/PE/ABS/PLA/PA/TPR

9. Lead Time 20- 40 Days

Q:Are you a trading company or a manufacturer?

A:We are a manufacturer with our own trade company.

Q: What kind of trade terms can you do?

A:EX-WORKS,FOB,CIF,DDP, DDU

Q:Do you often change the material to reduce the cost?

A:No,we will promise the mold quality and life ,unless the customer have the request .we are

sincerely treat all customers .

Q:Can you assure the quality ?

A:Yes ,We have a professional quality inspection department,the mold is strickly tested before shipment.also send the plastic products sample to you for checking the mold’s quality .

Q:Do you support OEM ?

A:Yes, we can produce by technical drawings or samples.

Q:Can I test my idea/component before committing to mould tool manufacture?

A:We have a professional design team who will evaluate your requirements for design and functionality and give you an answer.

Q:What type of plastic is best for my design/component?

A:Materials selection depends on the application of your design and the environment in which it will function. We are very glad to discuss the alternatives and give you best suggestions .